In 2018, the UK Department for Transport (DfT) challenged the Great Britain rail industry to remove all diesel-only trains from the network by 2040.

Over the next two decades, the railway will be undertaking large scale electrification programmes in order to achieve this target.

There are currently 13 Electrical Control Rooms (ECRs) monitoring the GB rail network and ensuring these ECRs are sufficiently staffed is essential for meeting the industry’s targets of reducing diesel-only trains from the network.

Any increase in the amount of electrification in turn creates an increased demand on the operational functions who are managing and maintaining this infrastructure. However, the steps required to adapt to this change are more complex than simply increasing the number of people on shift.

Rail organisations are required to consider the impact that changes to operational job roles, processes, and workload levels will have on staff’s ability to do their jobs safely and effectively. Appropriate action can then be taken during the design and development process to ensure that the future processes, equipment and working environment will meet the needs of the end users.

KEY STEPS FOR A HUMAN CENTRED APPROACH

This article summarises the steps that SYSTRA’s UK based Human Factors team have taken on a project over the past 12-18 months to help ensure that one of the largest ECRs in the UK will have sufficient capacity to manage the additional electrification being introduced by the GB rail network up to 2050.

Although this information relates specifically to ECR design, the same steps can be applied to change management projects in other disciplines.

STEP 1: ENSURE STAKEHOLDERS ARE INVOLVED

The electrified rail network is monitored by Electrical Control Operators (ECOs). Involvement of ECOs and Union Representatives was essential at every stage of the project to gain buy-in and trust from the staff and to enable collection of subjective data.

Due to COVID-19 restrictions at the time of assessment, discussions were held online to inform the initial data gathering. Fortunately, these restrictions were relaxed in time to allow SYSTRA to organise a direct observation of a 12-hour Saturday nightshift when peak workload demand is experienced to validate the workload models.

STEP 2: UNDERSTAND CURRENT OPERATIONAL PROCESSES

For people to access trackside equipment in electrified areas (e.g., to conduct maintenance), the ECOs are required to implement electrical isolations using specific processes to ensure that the isolations are correctly and safely implemented.

It is important that the processes and workflows are carefully mapped out and understood so that consideration can be given to how effective exiting processes will be once the demand for isolations increases. A hierarchical task analysis approach was used to collate this information to the required level of detail, and some simplified workflows were developed as a high-level summary of the steps involved.

STEP 3: IDENTIFY VULNERABILITIES WITHIN PROCESSES

A ‘vulnerability assessment’ was carried out using Systematic Human Error Reduction and Prediction Approach (SHERPA) to provide greater understanding of where the York ECR isolation planning, and execution process may be vulnerable to human error.

The findings of this vulnerability assessment have since been used to inform the design of a new ECR in Derby and also the reorganisation of the existing facilities in York. The vulnerability assessment has also been referenced by teams working on the design of new Supervisory Control And Data Acquisition (SCADA) software to understand how the numbers of alarms and alerts can be reduced to help manage workload.

STEP 4: BASELINE CURRENT WORKLOAD

A baseline model was created using a task-occupancy approach to create a profile that accurately reflects current peak workload associated with granting and revoking isolations. The key inputs to the baseline model were the number of isolations, task occurrences, task durations, and task complexity.

This analysis was presented as a model of demand for each hour of the 12-hour shift, and additional modelling carried out to develop models of scenarios that were not observed directly by our Human Factors team. This data was validated and accepted by the ECO representatives before being taken into the next stage of future workload prediction.

STEP 5: CREATE A TIMELINE OF FUTURE CHANGE

A list of future electrification projects and schemes was generated in consultation with the key project sponsors within the organisation. Predictions were made to quantify the additional single-track kilometres (STK) of electrification being introduced for each project. Discussions were also held to understand any potential increase in complexity or time occupancy demand for the infrastructure (e.g. increased number of control points).

The way that isolations are granted and revoked is also likely to change over the next few years, so any known changes to standards and processes were also considered at this stage.

STEP 6: PREDICT FUTURE WORKLOAD

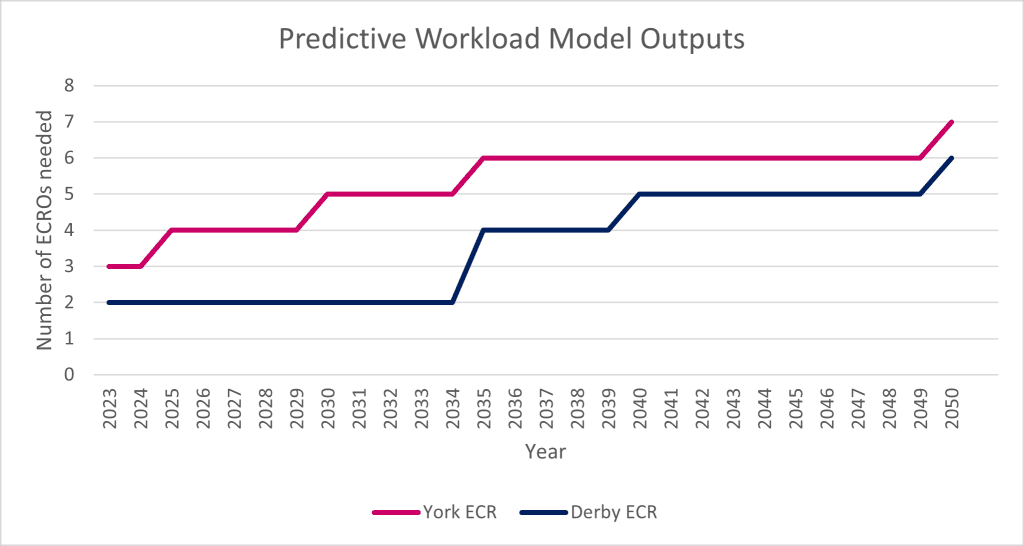

The baseline workload model was remodelled to predict the impact of future electrification projects on ECO workload and inform strategic decisions within the organisation about future requirements for ECRs and ECOs.

The predictive model required key inputs including baseline number of isolations, STK and complexity of infrastructure. Capacity was built into this model to ensure that time is available for rest breaks and for managing any unforeseen issues without becoming overloaded.

The predictive model outlines staffing requirements for the ECR over the next two decades and highlights when additional ECR capacity will be required to manage the workload.

STEP 7: DESIGN & BUILD OF NEW ECR

It was identified that a new ECR was required to manage a portion of the infrastructure to provide sufficient capacity for York ECR to manage new projects coming into the region.

Plans are now underway to build a new ECR in Derby to alleviate some of this additional workload demand. The predictive workload model was used to model the projected requirements for staffing arrangements for Derby ECR.

This work is supported with a register of Human Factors requirements that will ensure that the ECR’s of the future are designed and commissioned in an optimal way to meet the operational needs of the ECOs.

The contents of this article were presented by Charlotte Kaul at the 2022 Chartered Institute of Ergonomics and Human Factors conference held in Birmingham.

For further information, please contact Charlotte Kaul or Joanne Smyth.

Brazil

Brazil  Canada

Canada  China

China  Denmark

Denmark  France

France  India

India  Indonesia

Indonesia  Ireland

Ireland  Italy

Italy  Malaysia

Malaysia  Norway

Norway  New Zealand

New Zealand  Poland

Poland  Saudi Arabia

Saudi Arabia  Singapore

Singapore  South Korea

South Korea  Sweden

Sweden  Taiwan

Taiwan  Thailand

Thailand  United Kingdom

United Kingdom  United States

United States  Vietnam

Vietnam